PCB assembly, short for Printed Circuit Board assembly, lies at the heart of modern electronics manufacturing. As technology advances and demands for smaller, more efficient devices grow, innovations in PCB assembly processes become increasingly crucial. In this blog, we'll explore the cutting-edge innovations that are driving the evolution of printed circuit board assembly, with a focus on the contributions of Visoulia Electronics, a leading player in this domain.

Understanding PCB Assembly Process

Before delving into innovations, let's grasp the basics of PCB assembly. It involves the process of assembling electronic components onto a printed circuit board, creating a functional electronic device. PCBs act as the backbone of various electronic products, from smartphones and laptops to medical devices and automotive systems.

The Role of Visoulia Electronics in Printed Circuit Board

Visoulia Electronics has established itself as a prominent name in the PCB assembly industry. With a commitment to quality, innovation, and customer satisfaction, Visoulia Electronics plays a pivotal role in driving advancements and pushing the boundaries of what's possible in electronic manufacturing.

Innovations in PCB Assembly

-

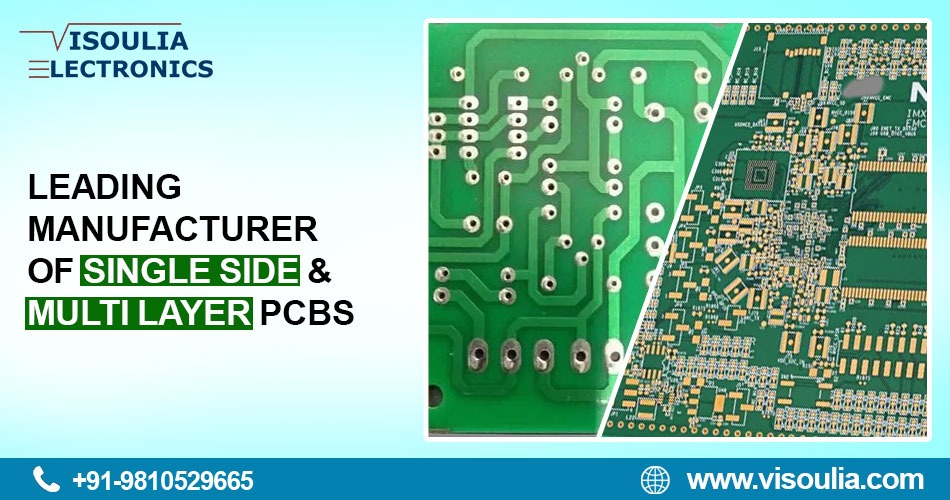

Miniaturization and High-Density Interconnects: One of the most significant trends shaping PCB assembly is the drive towards miniaturization. Visoulia Electronics, leveraging advanced manufacturing techniques, enables the creation of PCBs with high-density interconnects (HDIs). These HDIs allow for more components to be packed into smaller spaces, enhancing device functionality while reducing footprint.

-

Surface Mount Technology (SMT) Advancements: SMT has revolutionized PCB assembly by replacing through-hole components with smaller, lighter, and more cost-effective surface-mounted devices. Visoulia Electronics stays at the forefront of SMT advancements, incorporating innovations such as ultra-fine pitch placements, smaller solder joints, and improved thermal management for enhanced reliability.

-

Advanced Materials and Substrates: Innovations in materials and substrates are driving improvements in PCB performance. Visoulia Electronics explores and adopts advanced materials such as flexible substrates, high-temperature laminates, and conductive inks, enabling PCBs to withstand harsh environments, operate at higher speeds, and support emerging technologies like 5G and IoT.

-

Robotics and Automation: Automation plays a vital role in streamlining printed circuit board assembly processes. Visoulia Electronics integrates robotics for precise component placement, soldering, inspection, and testing, reducing human error, increasing efficiency, and ensuring consistent quality across production batches.

-

Smart Manufacturing and Industry 4.0 Integration: The integration of smart manufacturing principles and Industry 4.0 technologies is transforming PCB assembly. Visoulia Electronics embraces data-driven analytics, machine learning algorithms, and real-time monitoring systems to optimize production workflows, predict maintenance needs, and enhance overall operational efficiency.

-

Environmentally Sustainable Practices: In line with global sustainability goals, Visoulia Electronics focuses on environmentally sustainable practices in printed circuit board assembly. This includes using lead-free soldering techniques, recycling waste materials, minimizing energy consumption, and adopting eco-friendly packaging solutions.

Benefits of Innovations in PCB Assembly

-

Improved Performance and Reliability: The innovations driving PCB assembly result in improved performance, reliability, and longevity of electronic devices. Enhanced thermal management, reduced signal interference, and optimized component placement contribute to better overall functionality.

-

Cost Efficiency and Time Savings: Advancements such as automation, miniaturization, and smart manufacturing lead to cost efficiencies and time savings in printed circuit board assembly. Faster production cycles, reduced material wastage, and lower maintenance requirements translate to a competitive advantage for manufacturers.

-

Support for Complex Designs: Innovations in materials, substrates, and interconnects enable PCBs to support increasingly complex designs. This is particularly crucial in industries like aerospace, medical devices, and telecommunications, where compact yet powerful electronic systems are essential.

-

Alignment with Industry Standards and Regulations: Visoulia Electronics ensures that its innovations in printed circuit board assembly align with industry standards and regulations. This includes compliance with RoHS (Restriction of Hazardous Substances) directives, IPC (Association Connecting Electronics Industries) standards, and other quality assurance benchmarks.

Future Trends and Outlook:

Looking ahead, the evolution of PCB assembly is poised to continue at a rapid pace. Emerging trends such as 3D printing of PCBs, integrated photonics, quantum computing elements, and bio-compatible materials are on the horizon. Visoulia Electronics remains committed to driving these innovations forward, anticipating market needs, and delivering cutting-edge solutions to its customers.

Conclusion:

Innovations in PCB assembly, driven by companies like Visoulia Electronics, are reshaping the landscape of electronic manufacturing. From miniaturization and advanced materials to automation and smart manufacturing, these innovations bring tangible benefits such as improved performance, cost efficiencies, and support for complex designs. As technology evolves, the collaboration between industry leaders, innovators, and manufacturers will continue to propel the evolution of printed circuit board assembly towards greater efficiency, reliability, and sustainability.